Furniture edge options, materials and installation features

Protection for the end parts of cabinet products today is the furniture edge. It is offered by most manufacturers, and is also divided into several types. Depending on the purpose of the furniture, a certain type is used, which qualitatively protects the edges from damage. In order to know which edging to give preference to when choosing products, it is necessary to study their diversity, scope, and size.

Scope of use

Regardless of what type of edge is used, it is designed to protect the end parts of the product. Such an adaptation is especially necessary in the manufacture of inexpensive furniture from chipboard or chipboard. Since the composition of these materials contains harmful formaldehydes, which over time can evaporate their substances into the atmosphere. Edging materials allow you to close the rough edges, preventing the spread of fumes.

Another undoubted plus of such a detail is the protection of wood materials from moisture inside. As you know, penetrating into the pores of wood, water adversely affects it. If solid wood furniture is considered more resistant to moisture, then chipboard necessarily needs an edge for furniture.

The independent manufacture of furniture parts implies the mandatory use of edging. If this is not done, then during operation the unclosed edges of the product will be subject to rapid wear. Possible causes are accidental grazing of the edge, scratching with a sharp object, careless closing of the doors. That is why the processing of chipboard edging material is so important in the manufacture of furniture. To consolidate the information provided, it is necessary to highlight a number of functions that an edge performs - a special tape made from various raw materials for processing the edges of furniture:

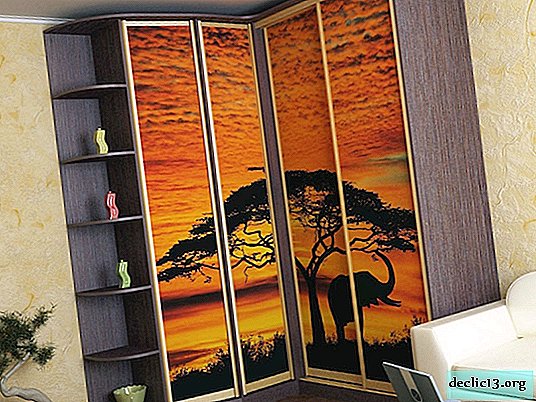

- Beautiful appearance of the ends of the products. During the purchase in the store, the buyer, first of all, looks at the aesthetic design. It is unlikely that he will want to install a sliding wardrobe, where the internal shelves look unfinished, and their edges differ in color and structure from the facades;

- Protection against mechanical damage. Edging materials are designed to protect fragile chipboard from moisture, delamination. Chips and burrs resulting from impacts can cause clothing clings and skin scratches. The laminated furniture surface may crack even when in contact with a hard object. If the edges of the parts are sealed with a border, the degree of damage and the chances of losing the attractiveness of the models are minimal;

- Protection of human health. As already mentioned, the edge plays an important role in maintaining the health of households. The more time furniture is used, the higher the risks of formaldehyde resin release from particleboard.

When choosing products for the home, it is worth paying attention to the specified subtleties. They will help to maintain the attractiveness of the furniture and extend the period of its safe operation.

Kinds

In modern furniture production, manufacturers offer several edging options at once. This is convenient in order to increase or decrease the cost of custom-made furniture. In addition, making products on their own - the question arises, what type of furniture edge to choose. In order not to get confused, it is necessary to understand in detail the features of each, highlighting their pros and cons.

| Title | Description | Advantages | disadvantages |

| Melamine | Sold in reels, attached only with glue. Edge tape can be single-layer and two-layer, made on the basis of paper. | A large selection of colors, the material easily repeats the outlines of furniture, no additional equipment is required for operation - everything can be glued on your own. Melamine furniture edge has an affordable cost. | The lack of protection against moisture, has a weak level of protection against mechanical damage. |

| PVC | It is made of polyvinyl chloride. It is available in two thicknesses, which are used for different pieces of furniture. The cost of the material is slightly more than the melamine analogue. | The edge will provide protection against acids, alkalis and moisture. The range is represented by a rich color variety. The PVC edge has a high level of protection against mechanical damage, and is also considered durable. Another undoubted plus is the incombustibility of raw materials. | The film is too stiff, which will not allow high-quality processing of the bends of the product. In addition, it can only be fixed using a special machine. Self-mounting is excluded. |

| ABS | The material of manufacture is acrylonitrile butadiene styrene. This species is considered the most resistant to all types of damage. | The most durable edge of all presented. It does not contain chlorine, which is safe for human health. The ABS edge has a fading resistant surface. It is soft and easy to cut, and also does not emit toxic substances. | No significant minuses were found for this type of edge. The only thing that can stop you from choosing is the high cost, because of which the price of furniture will increase. However, such a disadvantage is compensated by durability. |

| U-shaped profile | The use of U-shaped furniture edges finds its application on products that are constantly exposed to moisture. | The special form protects against mechanical damage to the ends more reliably. The material can be fixed independently with glue. Additionally, you can hide existing defects in the edges of the furniture. Prevents any objects from sliding off the shelves or table. | Such a frame is considered bulky and does not always look appropriate on furniture. |

Based on the proposed information, it can be concluded that the furniture edge of the ABS is considered the most optimal for home use - it reliably protects the edges of the products, preventing damage.

PVC

PVC U-shaped

U-shaped ABS

ABS Melamine

MelamineDimensions

To make the edging on the countertop or cabinet look natural and attractive, it is best to order the execution of this process by professionals. Before choosing ready-made furniture or handing over products of our own manufacture, it is necessary not only to determine the type of edge, but also to decide which size will be most suitable.

For each type of internal filling, it is necessary to use an edge of different thicknesses. So, for visible ends it is better to use a more reliable option.

Furniture edges are presented in the following sizes:

- Paper or melamine edge - thickness options for such a fixture - 0.2 or 0.4 cm. Manufacturers do not see the point of making it thicker, otherwise it will look ugly on furniture. Special attention should be paid to the self-adhesive furniture edge. Such devices are sold per meter, as well as in 200 m reels. Width - 26 mm;

- PVC - product thickness 0.4, 1 and 2 mm. Manufacturers often equip front ends with thin options, and shelves and drawers with thick ones. The standard width is 26.5 mm, and reels of 150, 200 and 300 m are produced;

- ABS - the width of such an edge is from 19 to 22 mm. Thickness can be 0.4, 1, 2 and 3 mm. For reliability, it is recommended to process the edges with the most durable edging of 3 mm;

- Laid on U-shaped profile - available in widths of 16 or 18 mm for chipboard materials, thickness from 3 mm and above.

Before processing furniture, do not forget to measure the thickness of the material - for chipboard this is 16 mm, for tabletops it will be 32 mm. Do not forget that the main enemies of chipboard are fungus, mold and bacteria, so high-quality edging is considered an obligatory step.

PVC sizes

PVC sizes Melamine Edge Sizes

Melamine Edge SizesCriterias of choice

The edge in furniture significantly improves the appearance of cabinets, drawers, tables, as well as any other cabinet furniture. Today it is available in various colors, and choosing an option to match the shade of furniture is not difficult. To make the selection process easier, and the result pleased the family for many years, pay attention to the following selection criteria:

- Material - speaking of material, edging can be divided into paper, plastic and rubber. The pros and cons of each of them have been described above. When choosing, it is worth paying attention to its compatibility with the material produced by the furniture itself;

- Width - popular sizes vary between 22 and 38 mm, so before cutting the product, you should choose the optimal width - it should completely hide the edges of the product;

- Thickness - Today, manufacturers use an edge from 0.2 mm thick. It is necessary to take into account the purpose and storage conditions of the furniture in order to choose the required thickness parameter;

- The presence of an adhesive layer. This criterion is important for people who want to independently fix the edge on the product. If the device does not have an adhesive layer, then it will not work to make a border;

- Type of fastening - distinguish between rigid, patch and mortise edges. Depending on the destination, choose one of the options. The mortise type is also divided into T-shaped and U-shaped;

- Type of surface - the edge coating can be glossy, matte, embossed or embossed. Consider this criterion to improve the appearance of your furniture.

Having studied all the indicators of furniture edges, you can safely go for a new set of furniture. When buying, pay special attention to the quality of the processing of edges and end parts. It is worth further asking the seller about the way to fix the edge. By purchasing furniture with a strong edge, you can provide them with a long service life.